Tools Introduction Class

Tools Feature & Advantage Introduction Class

Tools Operation and Application Class

Tools Maintanence and Repair Class

Tools Quality Checking and Certified Class

Tools Torque Introduction

Marketing Service Area

Member post

Hammer Introduction

Popularity : 1657Rubber Hammer -

The Series of 7848

The series are used for tires, laying basalt floors and processing other metal sheet materials that can’t be damaged or harmed. Rubber hammers are normally seen in construction industries and vehicle repairing and maintaining businesses.

| Production Code | Head Weight (g) |

|---|---|

| 7848-60 | 523 g |

| 7848-80 | 821 g |

Hammer (American style) -

The Series of 7811

A spherical surface is designed on the back of the round head. Not only the work of hammering center bores and metal sheets can be easily done, but also the needs of different precisions and the requirements of diverse applied forces can be met accurately.

| Production Code | Head Weight (g) |

|---|---|

| 7811-08 | 245 g |

| 7811-12 | 370 g |

| 7811-16 | 485 g |

| 7811-24 | 765 g |

| 7811-32 | 925 g |

| 7811-40 | 1125 g |

Engineer’s Hammer -

The Series of 7823

The flat side of the hammer can handle nails or flat surfaces without difficulty. On the other hand, the sharp side is more suitable for dealing with car sheet metals.

| Production Code | Head Weight (g) |

|---|---|

| 7823-10 | 1000 g |

| 7823-15 | 1500 g |

| 7823-20 | 2000 g |

Lump Hammer -

The Series of 7833

The series is designed with bigger hammer head and larger beating area, which makes them capable of hammering nails and drills of masonry architectures, or cutting gigantic rocks open.

| Production Code | Head Weight (g) |

|---|---|

| 7833-10 | 1000 g |

| 7833-12 | 1250 g |

| 7833-15 | 1500 g |

| 7833-20 | 2000 g |

Dead Blow Hammer -

The Series of 7851

Anti-seismic design greatly decreases the rebounding force while hammering. Compare to normal hammers, the surface or the working objects will be less harmed and the striking force will be distributed in average on the hammer side.

| Production Code | Head Weight (g) |

|---|---|

| 7851-08 | 227 g |

| 7851-16 | 454 g |

| 7851-24 | 680 g |

| 7851-32 | 907 g |

| 7851-40 | 1134 g |

| 7851-48 | 1361 g |

| 7851-64 | 1814 g |

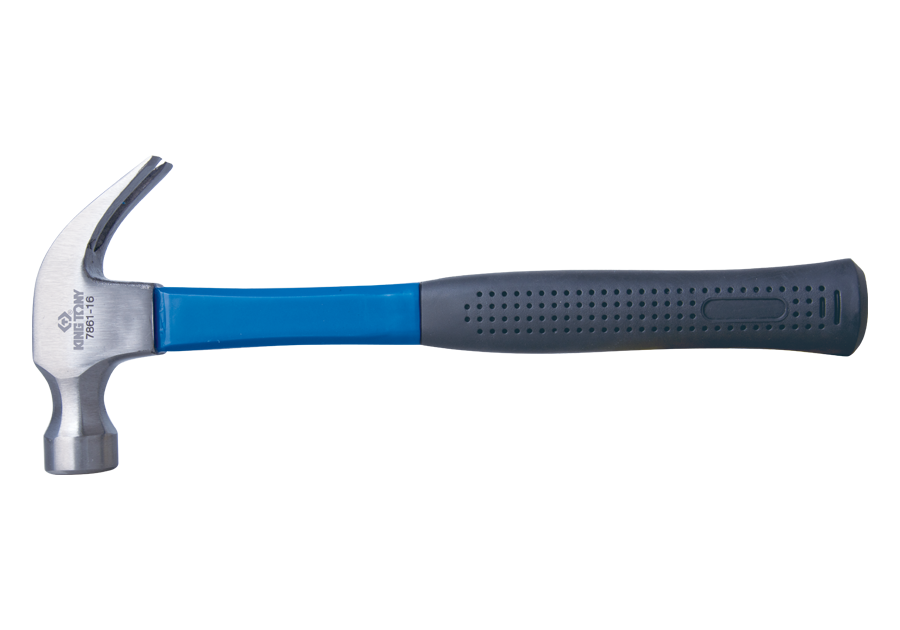

Fiberglass Claw Hammer -

The Series of 7861

Fiberglass Claw Hammer – The Series of 7861 Two curved claws are designed on the back of the hammer head, which makes nail pulling become an easy job for carpenters. Generally used in carpentries and woodworking industries.

| Production Code | Head Weight (g) |

|---|---|

| 7861-08 | 225 g |

| 7861-16 | 450 g |

| 7861-20 | 565 g |

| 7861-24 | 680 g |

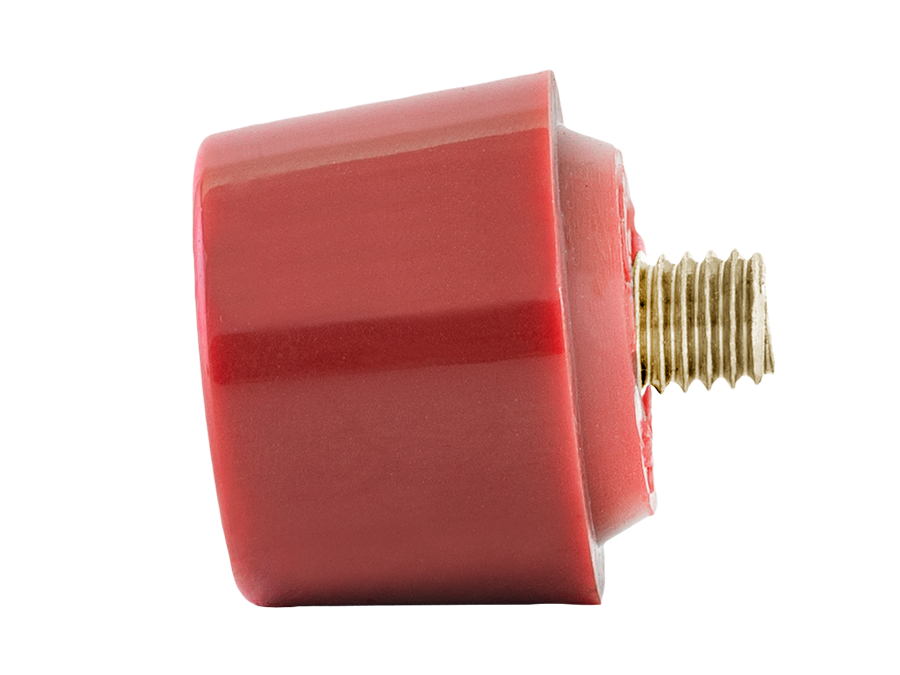

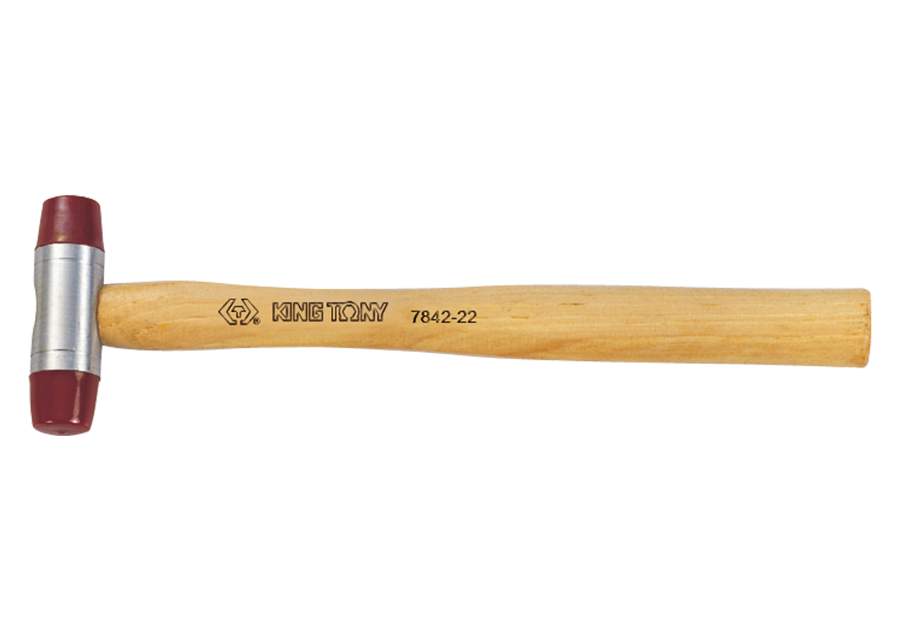

Soft Face Hammer -

The Series of 7842

The soft material (Polyurethane) is really efficient in shock absorbing that can greatly even the stress and force of the hammering area. The hammer is designed for soft sheet metals and suitable for precision industries. It is noticeably that the changeable hammer head can be displace into other suitable hammer head (softer or harder), according to users’ requirements.

| Production Code | Size of The Hammer Face (mm) |

|---|---|

| 7842-22 | 22mm |

| 7842-28 | 28mm |

| 7842-35 | 38mm |

| 7842-45 | 45mm |

| 7842-60 | 60mm |

Spare Faces For Item 7842 -

The Series of 915

The changeable faces are made from Polyurethane and is the accessories of The Series of 7842, which allows the soft face hammer to be suitable for different kinds of working environments.

A: Indicates the width of the hammer face.

H: Hard hammer face / S: Soft hammer face.

| Production Code | Size of The Hammer Face (mm) |

|---|---|

| 91522H/S | 22mm |

| 91528H/S | 28mm |

| 91538H/S | 38mm |

| 91545H/S | 45mm |

| 91560H/S | 60mm |

Recommended Products

Fiberglass claw hammer

7861

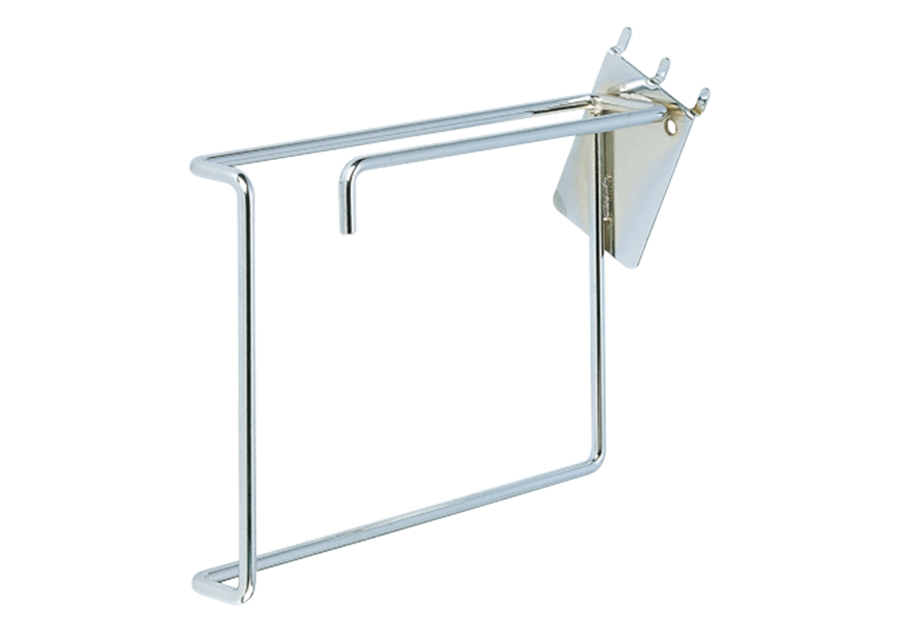

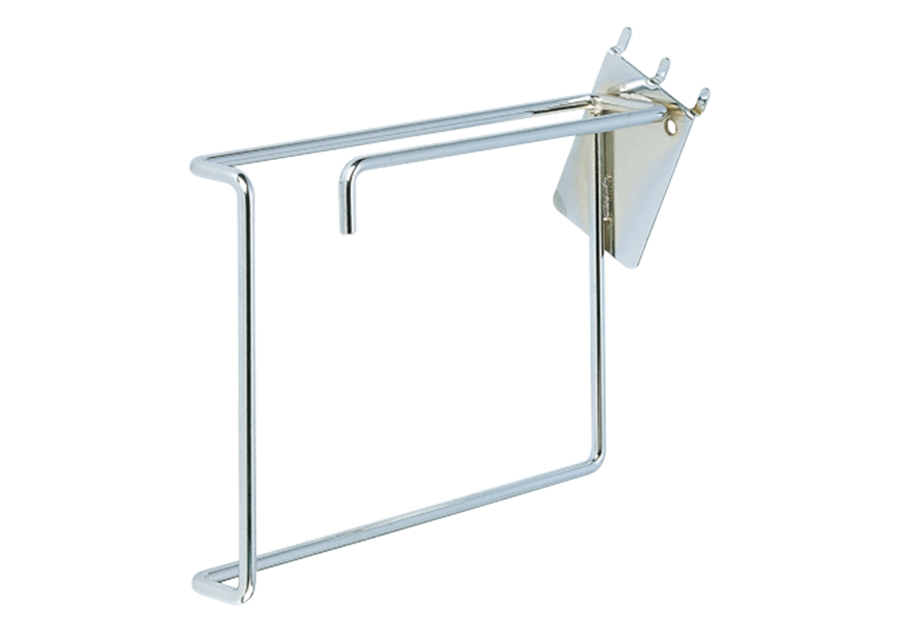

Hammer Hanger

91431

Rubber Hammer

7852

Sledge Hammer

7834

Rubber Hammer

7848

Hammer Hanger

91431

Hammer (American style)

7811

Hammer (German style)

7821

Riveting Hammer

7822

Engineer's Hammer

7823

Lump Hammer

7833

Dead Blow Hammer

7851

Soft Face Hammer

7842