Tools Introduction Class

Tools Feature & Advantage Introduction Class

Tools Operation and Application Class

Tools Maintanence and Repair Class

Tools Quality Checking and Certified Class

Tools Torque Introduction

Marketing Service Area

Member post

Pliers

Popularity : 31897Pliers-Basic Principle

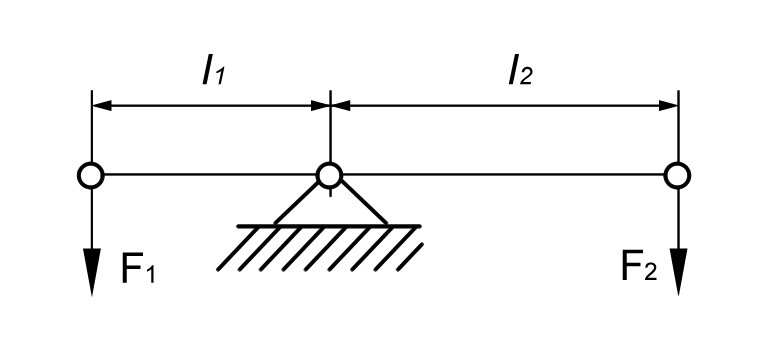

A plier is based on two arms of leverage design. The smaller external force which forced on the handle of pliers to transfer for bigger power. Pliers can clamp or cut efficiently.

When loaded the force on the arm of pliers, there will be another external force moved to increase along with leverage ratio.

In case of the pliers which have been produced a larger force, thus its distance (from the centre of the rivet to the handle) must be longer and the distance (from the rivet centre to the gripping jaws or cutting edge) must be as smaller as possible.

Differences between Pliers

|

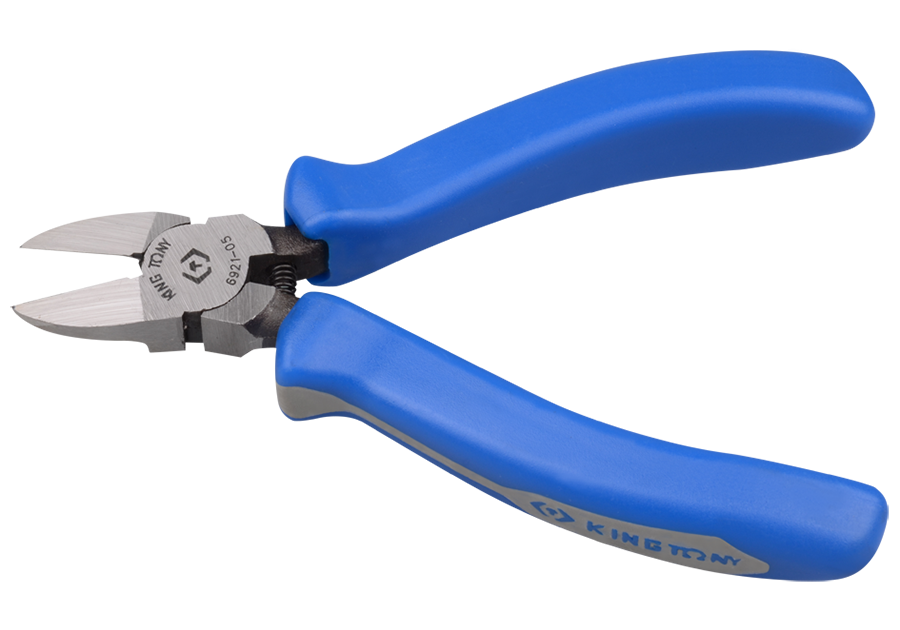

Cutting Pliers |

|||

|---|---|---|---|

|

For trimming or cutting objects. |

|||

|

Diagonal Cutting Pliers 6211 |

Heavy Duty Diagonal Cutting Pliers 6231 |

End Cutting Pliers 6411 |

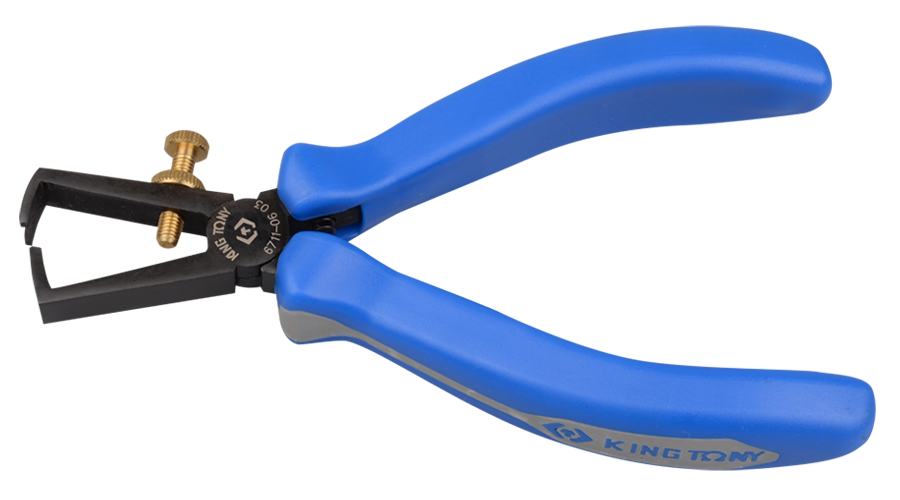

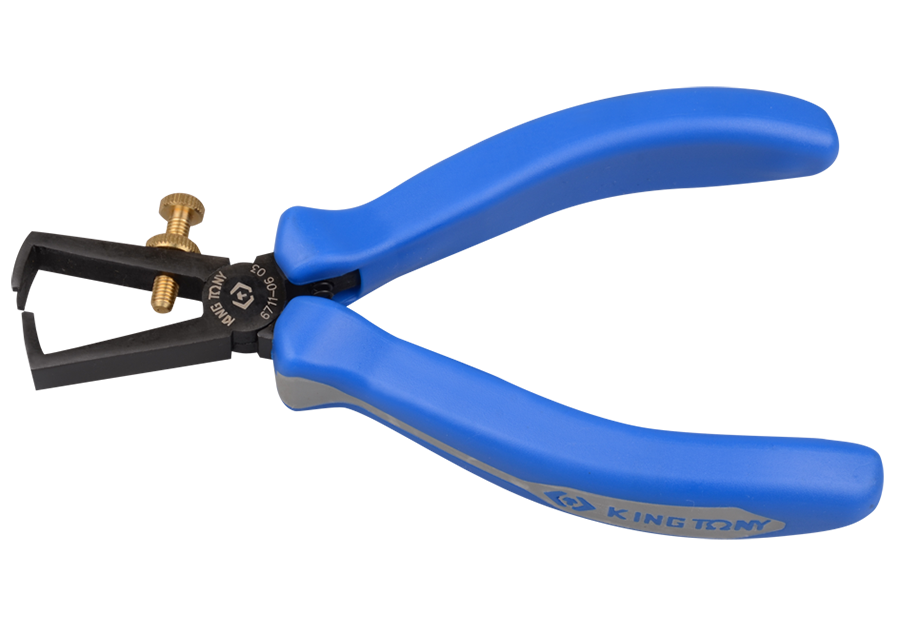

Stripping Pliers 6711 |

|

Gripping Pliers |

|||

|

For gripping objects. |

|||

|

Groove Joint Pliers 6511 |

Groove Joint Pliers 6516 |

Slip Joint Pliers 6463 |

|

|

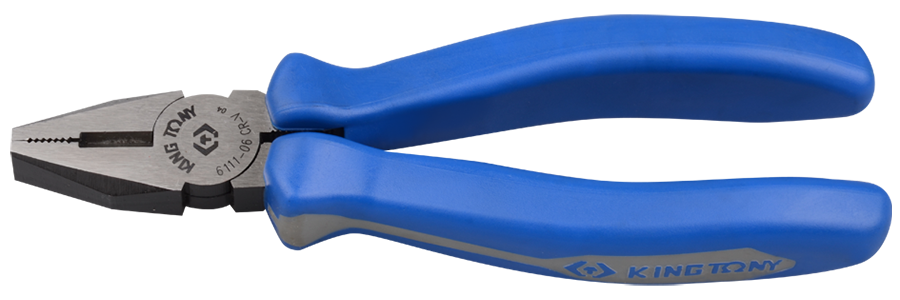

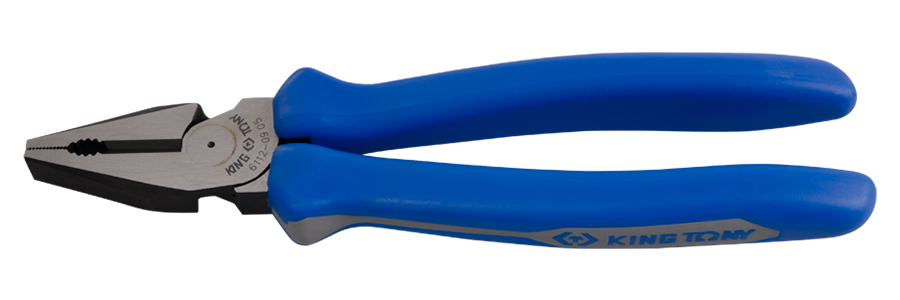

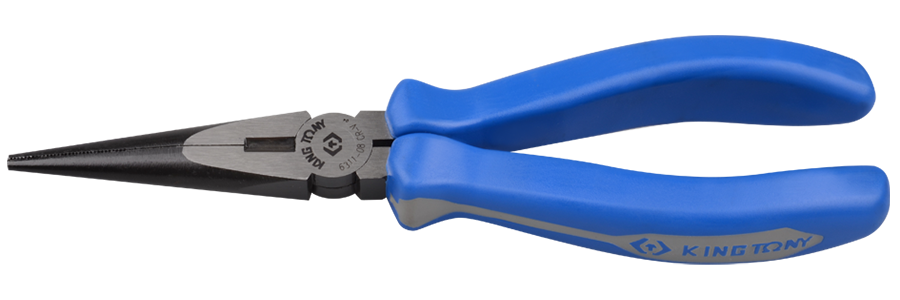

Combination Pliers |

|||

|

For gripping and cutting objects. |

|||

|

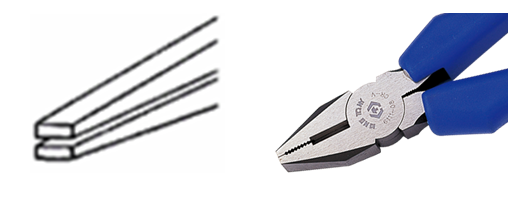

Combination Pliers 6111 |

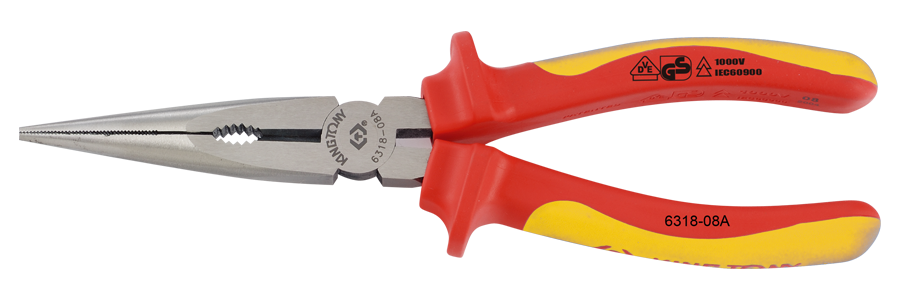

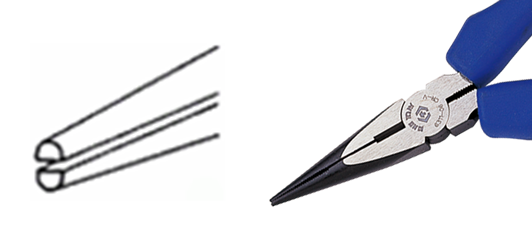

Long Nose Pliers 6311 |

||

Three Parts of a Plier

A plier can be separated into three parts.

-

Handles:

For holding.

Handles that was designed based on ergonomic allow users to hold the grip safely and comfortably. -

Joint:

Connection shaft of the plier.

The joint should be steady and without shaking while using in order to easily operate the plier with a single hand. -

Head:

With either cutting edges or gripping jaws.

The edges are ground percisely into standard shape. To cut the wires easily, both edges should be sharpened and aligned to each other accurately.

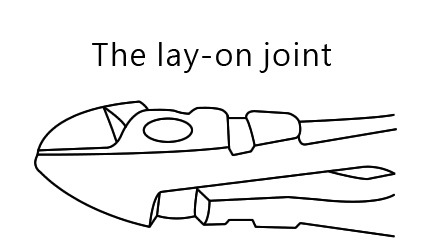

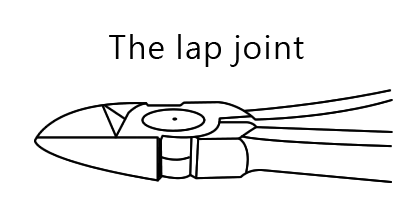

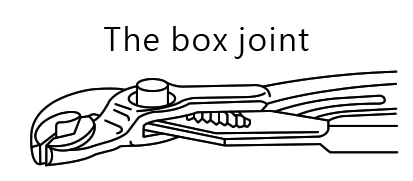

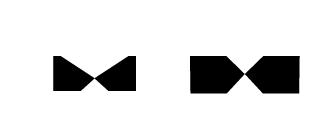

The Distinction of Joint Structure

|

|

|

| Such as the pincers. The two halves of the pliers are placed on top of each other - without being milled out - and riveted. |

Such as the combination pliers. Here one half of the pliers turns around the rivet but in a milled-out recess in the other shank. |

Such as the groove joint pliers. The box joint in which half of a pliers is pushed through a slit in the other half of the pliers. |

| Pliers is made by Alloy Steel , usually it will be produced by medium carbon steel (contained 0.45% carbon). But for high quality pliers whicH can be worked on industry, the pliers will be made of high carbon steel, like chrome vanadium alloy steel. | ||

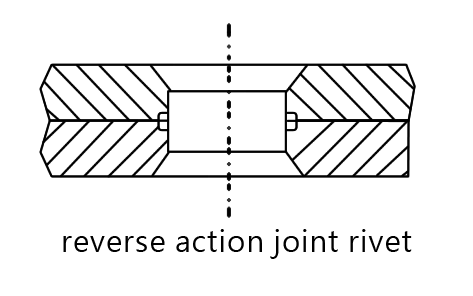

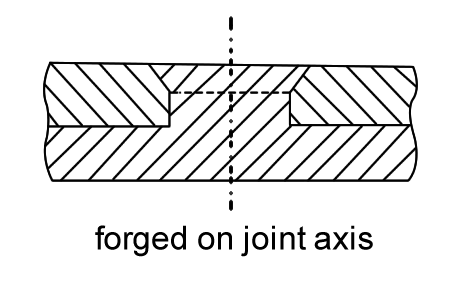

The Design of Rivets

There are two different ways to rivet the pliers:

Dr.Q reminds:

Use oil, such as WD-40, to maintain the polish surfaces and connection parts of pliers regularly, so they can be remained in good working conditions and extend the using lives.

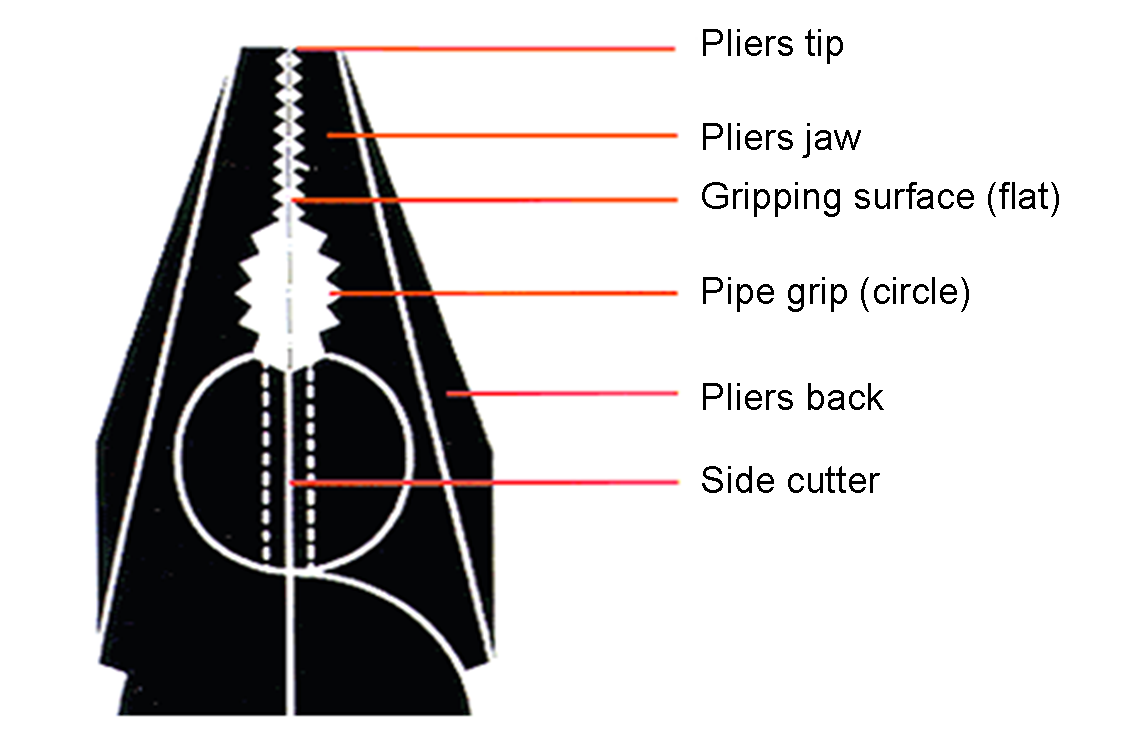

Pliers Jaw

| Flat | Half-round | Round |

|---|---|---|

|

|

|

| For example: The combination pliers are used to clamp things. |

For example: The long nose pliers are suitable for soldering works. |

For example: The electrician pliers are used to bend the coils. |

| There are three basic shapes of the pliers jaws, which are flat, round and half-round. Each shape is used for different purposes. | ||

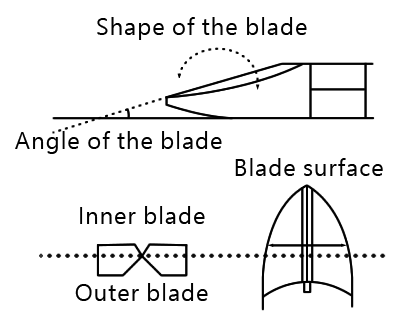

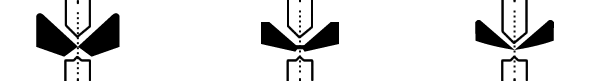

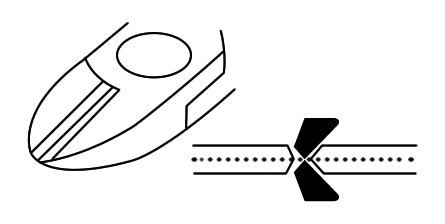

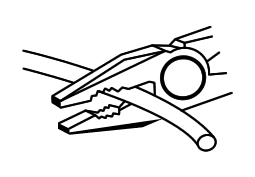

Direction and Position of Cutters

In order to cut wire in diverse thicknesses and materials efficiently, it is significant to choose a plier that is specifically disigned for the job. General pliers can be separated into three different cutting styles, which are diagonal, central and oblique cutters. Furthermore, all cutting edges were processed through high frequency procedures, or also be known as inductive hardening routine.

| Diagonal cutters | |

|---|---|

|

It is regarded as the most popular cutting style of pliers. Various lengths, shapes and cutting edges are suitable for different materials. It is regarded as the most popular cutting style of pliers. Various lengths, shapes and cutting edges are suitable for different materials. |

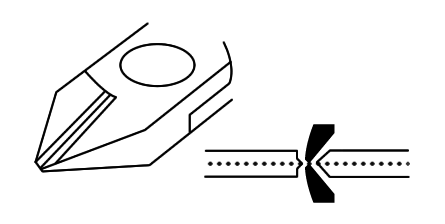

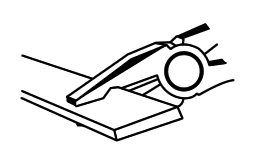

| Center cutters | |

|

They provide good stability at the cutting edges combined with a favorable cutting edge angle, i.e. a relatively small amount of force is needed to penetrate and "split" the wire. Consequently, the amount of hand pressure required is also reduced. They provide good stability at the cutting edges combined with a favorable cutting edge angle, i.e. a relatively small amount of force is needed to penetrate and "split" the wire. Consequently, the amount of hand pressure required is also reduced. |

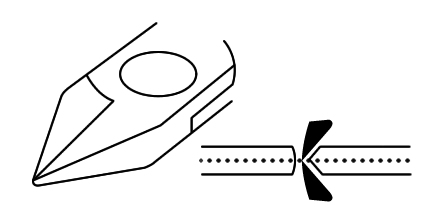

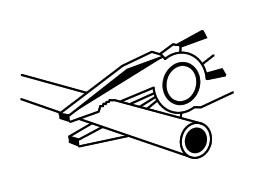

| End and oblique cutters | |

|

They are used where access to wire is only possible or advisable from a frontal or angled position. This can also apply where a wire has to be cut close to the surface. (In this situation, using a diagonal cutter, the fingers around the handles would be in the way). They are used where access to wire is only possible or advisable from a frontal or angled position. This can also apply where a wire has to be cut close to the surface. (In this situation, using a diagonal cutter, the fingers around the handles would be in the way). |

Main Cutting Types

Cutting Pliers can be divided into three different types of cutters

|

With bevel (standard) Cutting edges with a bevel are suitable for all wire classes, depending on the nipper design and capacity. |

|

With small bevel (semi flush) Cutting edges with a small bevel are suitable for all wire classes apart from piano wire, depending on the nipper design. |

|

Without bevel (full flush) Cutting edges without a bevel are only suitable for soft materials, i.e. lead and plastics. |

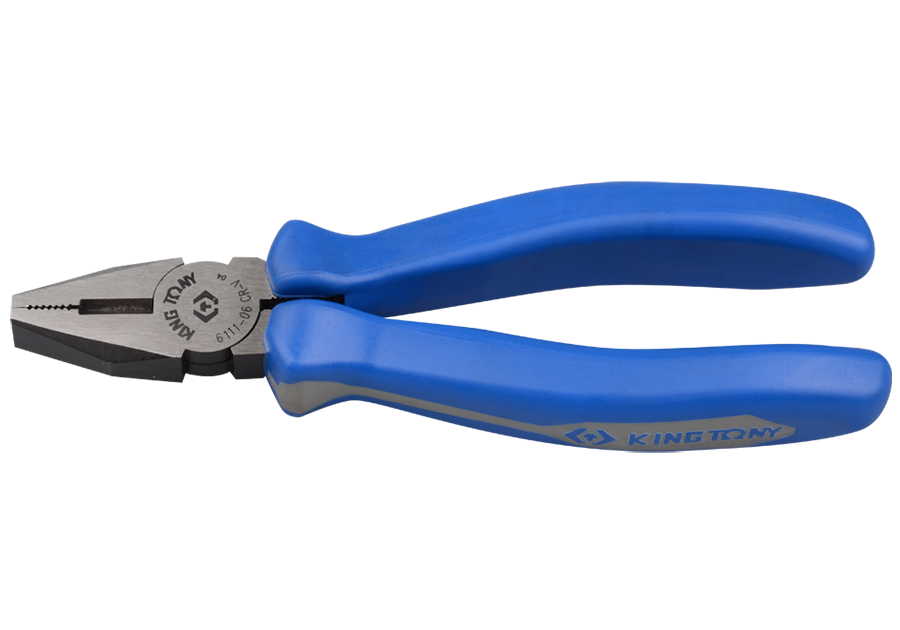

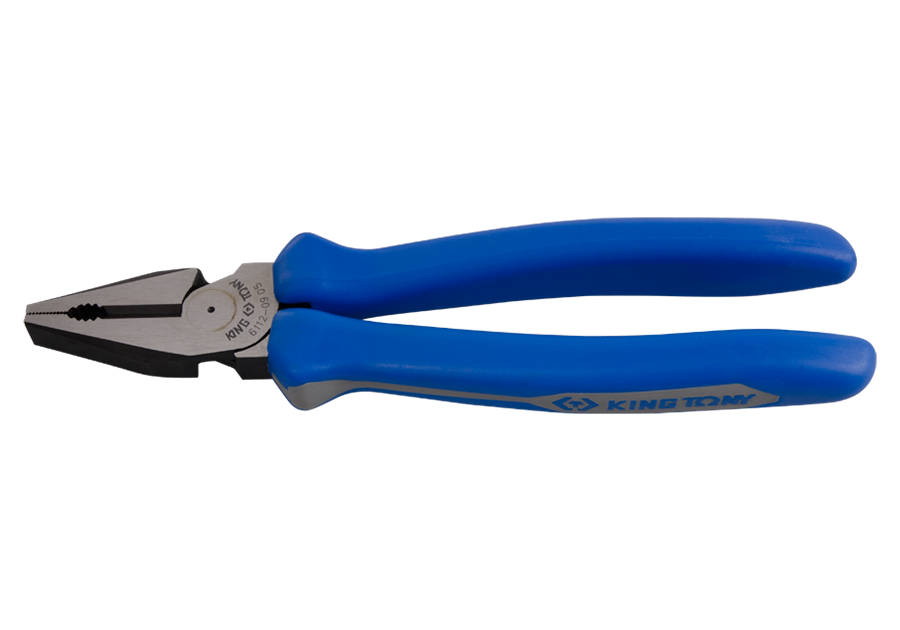

Combination Pliers

The combination pliers can do (almost) anything. The basic functions of the combination pliers are gripping and cutting.

|

|

|

| The cutting edges are suitable for cutting wire, nails, smaller cables. | The serrated jaw is applicable to grip flat materials and small tools. | The serrated round jaw is applicable to grip circle materials. |

| The 6112 series combination pliers use different leverage design, so they can cut wires more easier than general combination pliers and grip more solid. | ||

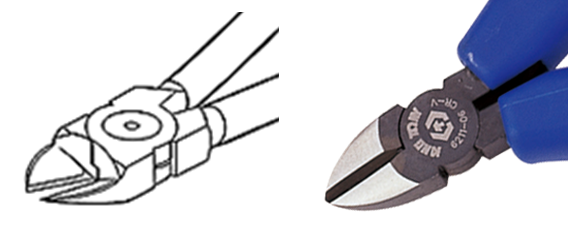

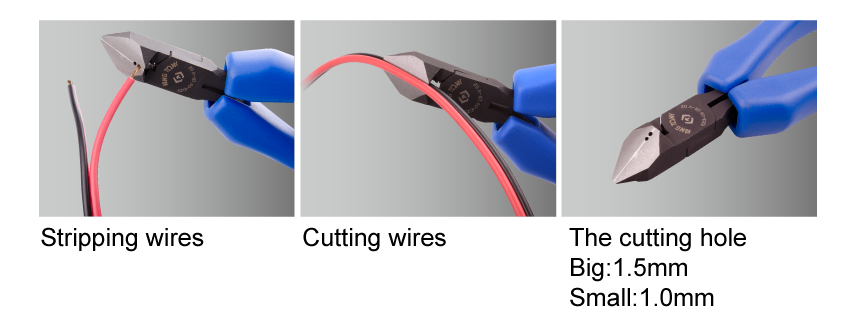

Diagonal Cutting Pliers

The diagonal cutting pliers are most commonly used. They are found in every electrician’s basic.

Principally, a good diagonal cutting pliers have induction hardened cutting edges which are sufficiently sharp and fitted each other exactly over the entire cutting edge length.

Please always placed the wire to be closer near its joint. It will increase the leverage and considerably reduces loaded force on it.

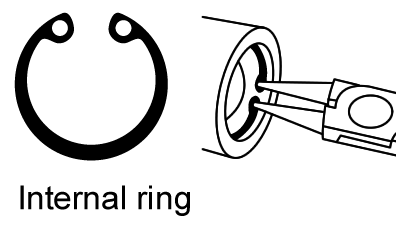

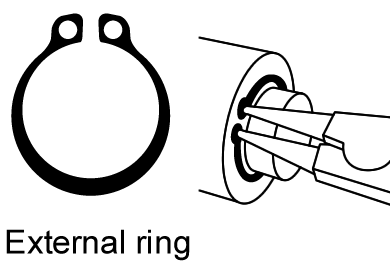

Circlip Pliers

They served to be assembled and disassembled C clip. These are used on all the construction of vehicles and machinery, and they are especially used for fixing bearings on shafts or into bore holes.

|

|

| Internal rings are used in bore holes. Using an appropriate size of pliers for internal rings, the ring is pressed together, thereby reducing the diameter and allowing it to be put on or taken off. | The external ring is used on axles and shafts. The pliers for external rings are used to enlarge the diameter so that the ring can be put on or taken off. |

The external ring is used on axles and shafts. The pliers for external rings are used to enlarge the diameter so that the ring can be put on or taken off.

Link to Retaining Rings and Circlip Pliers to know more~

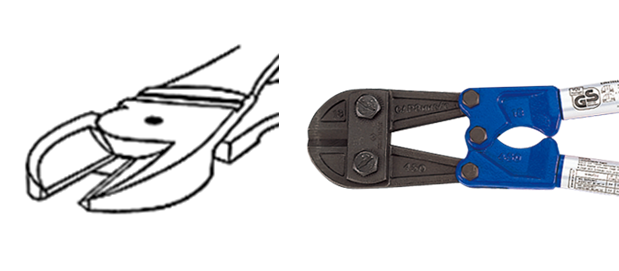

End Cutting Pliers

(Woodworking Pliers)

End Cutting Pliers are used widely and particularly popular because of their sturdiness. As their cutting edges are at the front and they are stable in construction, they are especially suitable for pulling out nails, clips...etc.

"Long nose pliers with cutting edge" is a standard design. Their function is similar with the function of combination pliers, but their shape is much slimmer. The difference will be on its head the its gripping jaws is longer and narrower.

Groove Joint Pliers

The groove joint pliers are gripping pliers with an adjustable joint. The width of its jaw and gripping capacity can be changed according to the set position.

The angular or oval jaw opening is usually serrated and is also referred to as the burner hole. Originally the water pump pliers were used to tighten the packed glands in water pumps in motor vehicles, which is how they got their name. Water pump pliers are suitable for gripping all kinds of items with larger diameters too, regardless of whether they are round, square or hexagonal.

A good groove joint pliers which must be with a bigger capacity of its adjustable position.

Locking Pliers

It can be clamped effectively when we are welding.

- Appearance: Curved jaws can be used in any place.

- Cutting Capability: Metal wires.

- Specifications and Capability:

| Production Code | HRC: 43 | Clamping Diameter (mm / inch) | Clamping Strength (FT) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 6011 | Wire cutting (mm / inch) |

Ο Standard |

Ο Large |

Ο Standard |

Ο Large |

||||

| 6011-05R | 1.2 / 0.0048" | 31 / 1.25" | 38 / 1.51" | 12 / 0.5" | 12 / 0.5" | 225 | 300 | 300 | 400 |

| 6011-07R | 2.3 / 0.091" | 41 / 1.63" | 48 / 1.92" | 19 / 0.75" | 19 / 0.75" | 300 | 350 | 450 | 600 |

| 6011-07N | 2.3 / 0.091" | 41 / 1.63" | 48 / 1.92" | 19 / 0.75" | 19 / 0.75" | 300 | 350 | 450 | 600 |

| 6011-10R | 2.3 / 0.091" | 47 / 1.88" | 54 / 2.15" | 19 / 0.75" | 19 / 0.75" | 480 | 550 | 900 | 1200 |

| 6011-10N | 2.3 / 0.091" | 47 / 1.88" | 54 / 2.15" | 19 / 0.75" | 19 / 0.75" | 480 | 550 | 900 | 1200 |

Recommended Products

External Straight Circlip Pliers

65SS

Long Arms Internal Angled Circlip Pliers

68HB-07L

External Straight Circlip Pliers

66SS

Internal Angled Circlip Pliers

66HB

External Angled Circlip Pliers

66SB

Internal Straight Circlip Pliers

66HS

Groove Joint Pliers

6516

Combination Pliers

6111

Hi-leverage Combination Pliers

6112

Long Nose Pliers

6311

Long Nose Pliers

6313

Diagonal Cutting Pliers

6211

Diagonal Cutting Pliers

6213

Heavy Duty Diagonal Cutting Pliers

6231

End Cutting Pliers

6411

End Cutting Pliers

6431

Groove Joint Pliers

6511

Stripping Pliers

6711

Internal Straight Circlip Pliers (Japanese Type)

67HS

Internal Angled Circlip Pliers (Japanese Type)

67HB

External Straight Circlip Pliers (Japanese Type)

67SS

External Angled Circlip Pliers (Japanese Type)

67SB

Slip Joint Pliers

6463

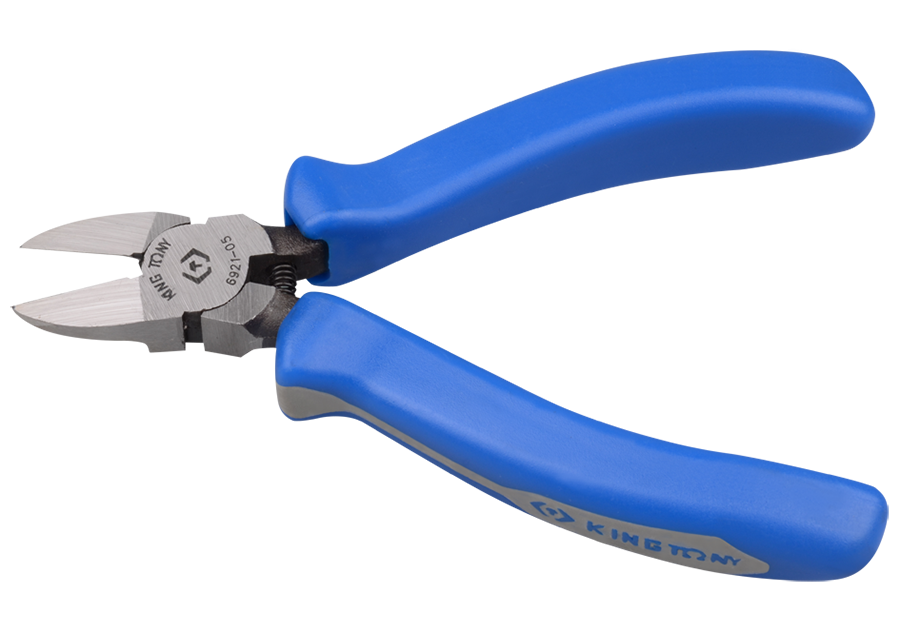

Plastic Cutting Pliers

6921

VDE Insulated Long Nose Pliers

6318A

VDE Insulated Diagonal Cutting Pliers

6216A

VDE Insulated Diagonal Cutting Pliers (Heavy Duty)

6236A